JLOX: new high performance metal filament

for metal 3D printing

JLOX – new high performance metal filament for metal 3D printing that can be used in suitable filament 3D printers as well as in the Xerion Fusion Factory 3D printing production line.

MiMtechnik has developed a new high performance metal filament for 3D printing based on its significant experience in the metal injection moulding (MIM) sector: JLOX.

Similar to plastic filaments, JLOX metal filament is offered on a spool and can be used for metal 3D printing on all suitable open filament 3D printer systems that employ filaments with diameter of 2.85 mm. The complete metal component is obtained after debinding and sintering of the 3D printed component. The whole process of 3D printing, debinding and sintering with fast cycle times is offered by the Xerion Fusion Factory production line. Alternatively, the debinding and sintering services can be offered by MiMtechnik.

Metal sintering & 3D printing service

for JLOX metal filaments

We take over the tasks of debinding and sintering of components that are printed with our JLOX metal filament. Per request, we can also carry out the complete manufacture of your components according to your STEP file.

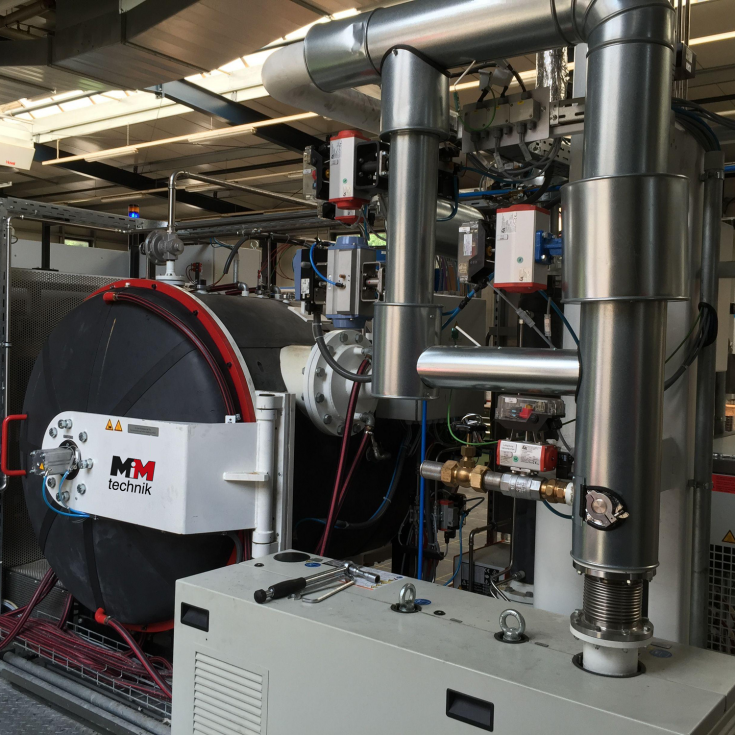

MiMtechnik GmbH possesses the decisive long-term experience in debinding and sintering of metal components.

You print your metal components on a suitable open filament 3D printer system using our JLOX metal filament and then we carry out the sintering service.

Sintering service for components printed with JLOX metal filament include:

12 hours debinding in acetone bath (up to 10 mm wall thickness)

Sintering with process gas (hydrogen for JLOX 316L and nitrogen for JLOX 42CrMo4)

JLOX metal print service:

Definitely, we can also print the metal components for you. Simply send us your file and receive your ready-to-use metal components in 2 weeks.

3D metal filament data JLOX-316L

GENERAL

Corrosion- and acid-resistant steel

TYPE

Ferrous-based material

SIZE

Ø 2.85 mm

MATERIAL

316L – 1.4404 – 1.4435 – V4A

PROPERTIES

– non-magnetic

– good corrosion resistance

– minimal hardness

– good ductility

– austenitic

APPLICATIONS

– polished components

– apparatus construction, chemical industry, medical instruments, watches and jewellery

TYPICAL COMPOSITION

DIN 17851

SINTERING

1340-1390 °C under hydrogen atmosphere

3D PRINTING PARAMETERS

135 °C Düse <0.4 mm with 0.05-0.3 mm layer thickness